Last Spring, my friend Craig Corvin (who is a bespoke shoemaker from Seattle) passed by London, while on a mini European tour, in order to stock up on the ‘ol shoemaking bits that one needs for the tool heavy profession. While on his short pit stop in London, we managed to get an evening in of pint sipping, football (soccer) watching and shoemaking discussion. While he is far more advanced than myself with regards to shoemaking, he was eager to know about my experience in Italy and how the idea of shoemaking (and it’s process) differs from the way in which he learned. Funny enough, both Craig and I (being from Seattle) took our first dive into shoemaking by attending this Shoe School in Port Townsend (outside of Seattle) in the hopes to gain some groundwork before going off to Europe to study under a master European shoemaking. As most of you know the story, I went to Italy, but Craig found himself studying under Marcell Mrsan (of Koronya) learning the more Austro – Hungarian form of shoemaking. After his stint with Marcell, Craig took it upon himself to continue the shoemaking, teaching himself the rest of the process, like last making and closing (sewing the upper together). He set up a little workshop, in the backyard of his home, and started making for himself and family members, before slowly moving on to take on clients as well.

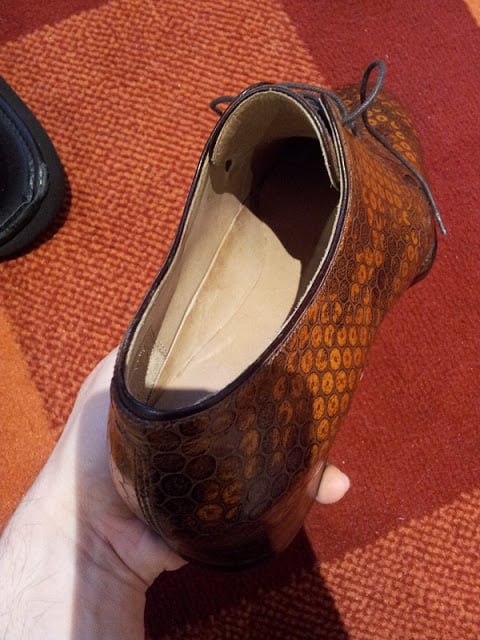

So while there together, Craig kindly offered to make a pair of shoes for me, assuming that I would use my own last. In part it was a gift, as a thank you for supporting him, as a congratulations to me for working hard on my own line, and as a constructive way to get some feedback on his making abilities. I was happy to accept, especially as I had this crazy skin that I was eager to see made up into a beautiful wholecut model. I left him my lasts and the leather and one week ago, this lovely shoe is what came back to me. Needless to say, I was very pleased with the results! While this isn’t a model that I would wear everyday, I do find it to be something that will go nicely with summer attire, differentiating itself from all of the other tan shoes out there. And just in case you are wondering, it is not snakeskin. It is a printed calf, both in color and texture….So what you are seeing here is a shoe that is entirely made by hand, all by Craig, even the upper making and that lovely top beaded line that holds the upper and the lining together.

Craig, I am sure, would be the first one to admit that his making abilities are not quite yet on par with your G&G’s, your Lobbs, Corthay (bespoke) etc. And while I do agree with that, I do feel that he is not far off, and that he might sell himself a bit short sometimes. Upon inspection of this shoe, I can say that looking at it from more than 6 inches away, it looked perfect. Looking up close, you will see slight imperfections (that you do in many bespoke shoes) in the finishing detail, but this is not something that is abnormal, as the finishing details are the hardest things to master, and can take some makers 10-20 years to perfect. Now, while I will say that the shoe is not “perfect,” (hence the sarcastic quotations) I will say that considering that Craig only charges around the third of the price of most European makers, that they are well worth their price and so much more. For the price that he charges, you can just buy G&G, Lobb, Corthay or any of the likes with a bit of change left over, but only for their RTW. Their bespoke is triple that, at least. That being it is more than justifiable that the waist is not “perfectly” shaped, or that the heel does not look like a razor cut edge. But at that price, I would honestly go for his shoes all day over any RTW shoe in the world. And then again, bare in mind that he also does the closing. Come to think of it, I don’t know how he makes any money from the profit margin (and living in America, where things aren’t cheap), after all the hard work and hours that he must put into a pair!!�

And while I did not pay for the shoes, I would say in all honesty that if I had, I would have been more than pleased as I believe that his making abilities are superb, especially as he has taught himself a lot of the making process. The shoes are amazingly comfortable and feel far better than any of the shoes that I made myself on this very same last. The extra bit of arch that he inserted into the sock is truly helpful and the feel of the shoe makes me think that I could walk around rocks all day and not tarnish the shoe at all. Basically it feels supportive and indestructible. I am quite pleased and am happy to say it…..That being, if you are one of the people that have always aspired to go bespoke but could not quite afford a ticket to Europe plus a $4000 price tag, well Mr. Corvin could very well be your answer. To see the actually making of this shoe, please visit the link below:

Looks brilliant. I can’t believe he could be that cheap either – maybe it’s worth sending him some lasts!

Your shoes are on Craig’s front page today!

Those shoes are amazing! I wouldn’t necessarily want to copy yours exactly, but I’d be interested to know where you found that printed skin, as i would expect them to have other interesting ones as well. I’ll also be giving your friend Craig a serious look, as the saving on not having to travel to Europe by itself could bring a pair of his bespokes much closer to attainable than any of the famed European makers. Thanks for sharing!

Alex B – it is worth it!!

John Koontz – nice one!

Anon – the skin was given to me but I believe that it was from Crack’s in England (http://www.aacrack.co.uk/)…you should give him a look, he makes a good shoe at a great price…hard to beat it!

-Justin