|

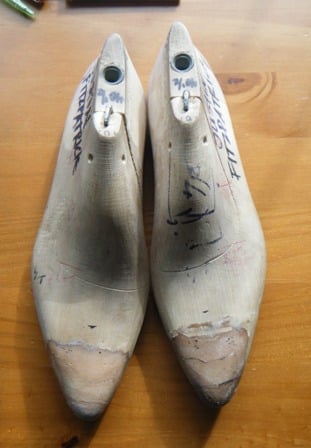

| Finalized product will have metal eyelets…..my round last shown below |

A shoe�s last is very important, for more reasons than one. Firstly, it makes up the shape of the shoe and there are about a trillion and one variations that one could come up. Secondly, it affects the fit, and thus the comfort of your shoe. So ever if you happen to design the coolest pattern and make the most pleasing shape one�s eye could handle, but fail to get the arch and fit right, it�s pretty much as good as garbage. I know that this is harsh to say, but�s it�s true and you need to know this. And this is why a shoe�s last is so important and is something that you need to make sure that you get right. But how do you do it? Well, there are several options when starting your own line. First, you can always just use the stock options that the factory will provide. These are most likely going to be lasts that have worked before and have been tried and tested. The only problem with this is that you are then using a shape that has been done before. It�s not yours, it belongs to someone else and more likely than not, it will be used on other shoes that are in the marketplace at the same time that yours are. This may not bother you, but for some it might. Therefore, the second option would be to create your own. But this is where the difficulty comes in. �

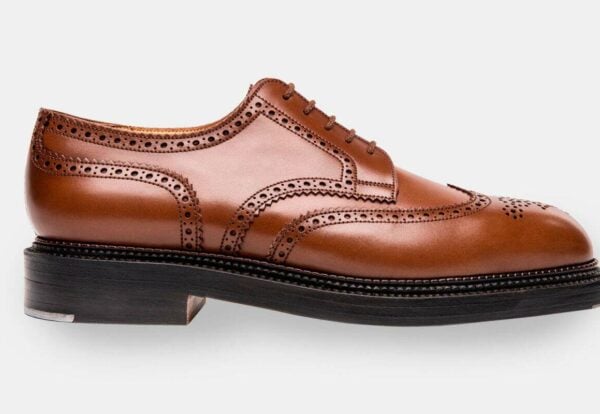

| From above (bespoke) to this (factory produced) – although there have been adjustments since this pic |

Allow me to explain what I have done in order for you to get an idea of the possibilities that are out there. So, I have two bespoke lasts: one that I made myself for myself and another that a bespoke lastmaker made for me. While mine is not bad (in fit), it is evident that the one that the lastmaker made for me is far superior. Therefore, what I did was take my two lasts to a place that manufactures lasts and asked them if they could mimic the one that the lastmaker made for me, only changing the width proportions of it. What that means is because my foot is quite narrow and therefore my last would be too, I had them alter the new last in order to be of medium size proportions, i.e. become a standard medium fit, but keeping all of the curves/bespoke shapes of my last. For the last that I made myself, I asked them the take the toe of it, and put it on the body of the last that was made for me by the lastmaker, while of course changing the width proportions. What that meant, was that I was going to get the arch of the last made for me by the lastmaker but the toe shape of the last that I made for myself. Now this did not all work out perfectly in one go, but after a few re-creates, a bit of shaving off the edges etc., I now have two lasts that are unique to my brand and that I can call my own.�

|

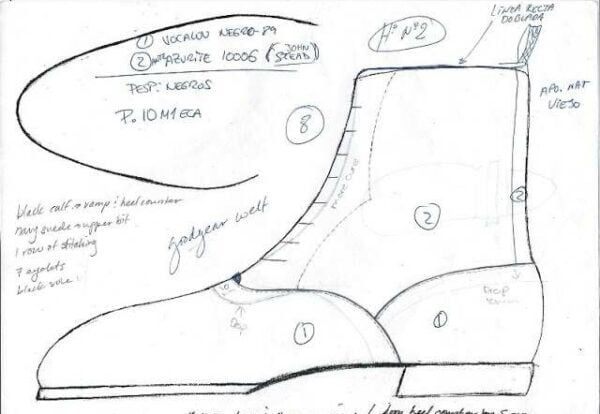

| My wholecut……with brogueing….on pointy last, shown below |

Will my lasts fit everyone? No, probably not. But you cannot make one last to fit all. You can only do your best to make a last that can fit as many as possible (unless of course, you are going to do width ranges). It�s best to know your audience and try to make as close to them as possible. In England, where my company is based and where I will launch from, men tend to have a broad foot with a high instep. Therefore, while my shoes are all going to be labelled as an �E� fitting (which is medium), it will be slightly broader (in fit, but not in look) than the average �E� that is out there. But in order to make sure that you are going about it right, you have to conduct trial fits i.e. you have to make up pairs of shoes, then give them to the �average� person to wear and ultimately to test. They will then need to give you feedback on the fit and how it feels. With that you can adjust accordingly.�

| Evolution from above to this – again, modifications have been made since this photo |

It�s no easy thing creating lasts that are going to do the trick, and you will never really know how well they work until your line is out. But it�s the part of the journey that you have to make sure that you try your absolute hardest to get right��or else there could be some serious consequences�..

Stay tuned next time for a bit on the manufacturing side of the shoe industry.

|

| Loafer last that belongs to factory – not mine – but good nonetheless! |

Can’t wait to see th� final results! Like the mix of jeans and leather on the 1st photo

The suspense is killing me..waiting to try one on and see if your “EX” is “X” enough!

Are you doing European or UK sizes?

Alex G – Glad to hear it Alex! I appreciate the words….

Alex B – You are telling me!! I am like a kid counting down the days til Christmas!! I am sure that you will manage. My leathers are French calf skins, so they are soft and pliable…not stiff like traditional English shoes…..this will help for sure…they will be in UK sizes

-Justin

As soon as you have a 9.5 in your hands, in any model, I want to come by and try!