The hardest thing about starting a shoe line, or really just starting your business plan to a shoe line, is coming up with the price that you want to sell your shoes at, retail value. There are so many factors that will dictate what that final price will be, factors that you might never have thought about before, like the fact that retailers will mark up a shoe’s wholesale price 2-3 times over (e.g. wholesale price = $100, retail price would be = $200-$300). But those are just the two end prices, let alone the cost of production versus the cost of what, me, the shoe designer, would pay the factory, for each pair. This is what I am going through right now, as I decide where I want to make my shoes (Italy vs. England) and how I am going to be able to do my best to balance price vs quality. Because all in all, I want to make a good quality, goodyear welted shoe, that can last a good amount of time for my customers, but at the same time don’t want them to retail at way above the common man’s price range. This dilemma is a big one, and has made me realize why some shoes are indeed, very expensive.

Shoes at Top of Page: Allen Edmonds

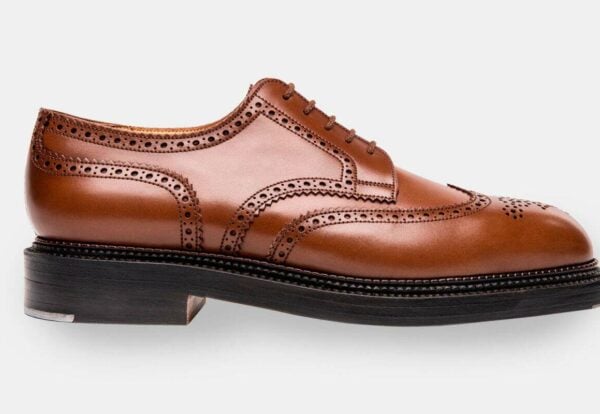

Shoes Above: Grenson

In my opinion, globalization is the reason that I, and many other designers/makers are having or had this same problem. If you can remember, there used to be a number of fantastic shoemakers in the US, that made good quality shoes, such as Florsheim and Johnston & Murphy. But now, due to the amount of cheap labor and materials, many of those same companies decided to take that lower-priced route and shirked on their quality of labor and materials, thus resulting in shit shoes. Granted, there were a couple of American makers that stood their ground, such as Allen Edmonds and Alden, but even now, you can see where the quality is slowly deteriorating on Allen Edmond’s models, or you will find the same quality, but the price has gone up and you no longer get a pair of extra laces, nice shoe bags or some sort of shoe horn. It’s just the shoes and some cloth that they wrap the shoe around. So when you wonder why shoes are so expensive these days, thank globalization for it, because in reality, the high quality, goodyear welted shoes that you think should be cheaper, in fact should not! Grenson, for example, can make a beautiful, well-made shoe, but they have now chosen to re-evaluate their company, and with that decided to start mass producing by having shoes made in India, with either glued or blake stitched soles so that they could retail at $300-$400. Because their high end goodyear welted shoes, would sell for 350-450 GBP, which would then result to around $700. It’s not a bad thing, it just is what it is. Companies want to stay afloat, and unfortunately because of the way the world is right now, that’s what they have to do.

Shoes Above: Stefano Bemer

Back to my dilemma. I am sitting here thinking, ‘Okay, for my customer, I want to make a high styled shoe. Something classic but with a modern touch yet it is absolutely pertinent that I make a good quality shoe or else I would just be a complete hypocrite.’ This is what I tell myself. But then, I am stuck with knowing that it will cost me around 120 GBP (minimum) to buy a goodyear welted shoe with high quality leathers from a British factory (and who knows what it actually cost them to make it?). Then let’s say that I only want to make 50 GBP profit on each pair. (That’s not asking too much now!) That would mean that my wholesale price would be 170 GBP to sell to retailers. So let’s say that I sell it to retailer X in London. Their price would at least be 425 GBP. You might say that this is not a lot, and when comparing it to a pair of John Lobbs, it’s not a super high price in reality. But now, considering that the British pound is the strongest form of currency and it’s market will only be a small part of my business, we have to take into account what that same 170 GBP wholesale shoe would sell for around the world. So now let’s assume that retailer Y in the States wants to buy my shoes (and the x-rate is 1.6 dollars to the British pound). That would make my wholesale price at $272 which would then make the retail price $680 and that does not even take into account the tariffs that US custom’s is going to tag on. So, to make a simple goodyear welted shoe, with some nice leather that will last the average man around 10-20 years with re-soles, you are looking at 425 GBP or around $700. How many people can afford $700 or 425 GBP shoes? That’s my dilemma!

Shoes Above: John Lobb

Hey Justin!

I’ve been following your blog for sometime and if you were to make your own company that would be awesome (MAKE CHEAPER BALMORAL BOOTS!!)

In your post you seem to comment on British v.s. Italian, although you only seem to talk about production in UK!

How would production in italy be? And is blake actually that bad? I mean Berlutis and a few others use blake and it seems ok (i have a pair from non-famous company which i have used for 5 yrs!).

Guys like Ron Rider have made it big with italian companies (He uses Martegani right?) and I’m sure if you can do similar but with your own designs it would be killer!

All the best!

Justin, i must say this has been a very insightful post and has kind of opened my eyes for the pricing issue many brands probably face.

I�d definitely would buy a pair of your shoes, even if that meant spending a good deal of my monthly income. Quality and passion need to be honoured and financially rewarded.

As for the production style: i don�t care if they were made by blake or goodyear standards and i probably couldn�t tell the difference wearing either.

All that counts is craftmanship, style and the feeling that you get what you pair for.

Keep us updated on your search!

Couldn’t agree more with the previous comments left on this post. Overall a consumer’s wants and demands are lots of any product, specially if they are paying the hefty price for such. In this equation, all you have to make sure is that the superb quality and craftsmanship ”hand made” is there, even for an un-experienced eye! If you could get a pure amateur to really notice how much quality in hand your line of shoes truly are you are half way there. Let’s say for example, the scent of that superb leather you could smell a mile away. If you could achieve this you basically have half of the world’s population in your hands. Once this is done, you could price your line more as much as you desire.

Conclusion..make the average joe notice you, seduce him..then give him the bill.

I would definitely buy your shoes at $700 and up. But please by all means be original. I hate all these brands that copy each other and it turns into a mess and lots of confusion over who is who.

All the best!

Julio B.

Hi justin

Nice post, pricing is really a issue! You will be surprise how many people can afford $700 for a pair of nice shoes, but then I have a new dilemma for you!

“Why people will buy my shoes when they can have a well know firm for same price?”

from the 1st comment:

“In your post you seem to comment on British v.s. Italian, although you only seem to talk about production in UK! How would production in italy be? And is blake actually that bad?”

In Italy you can have hand made bespoken goodyear

for 350 euro, but these artisans still have bed time because customers prefer spend double just for the label.

Hello Justin,

have you thought of bypassing traditional Retail?

Since your Customer base will probably spring up around the People that read your Blog or that meet you at Gieves and Hawkes.

Feit Shoes from Australia stopped selling through retail and now only sell directly to the customer. While their style of footwear is at the opposite end of the spectrum from yours, they make goodyear welted, hand made shoes.

It seems they get a larger cut, and at he same time can offer lower prices.

I’m not sure if that could be a viable Plan, but it seems like a interesting business model.

@Julio B. As sad as it is to say this, I think you greatly overestimate the average person’s willingness to pay for quality. Getting people to notice that they have something of high-quality in front of them is great, but it’s a far cry from having half of the world in one’s pocket – even if you neglect buying power altogether.

I wish it wasn’t so, because the world would truly be a better place if people valued quality over labels. Until then, some more work is required.

Hi Justin,

I think that you have admirably summed up the problem, except the solution which is what most manufacturers and stores end up with is that they take smaller mark-up margins on name-brand items. Also, typical margins for a designer are 2 1/2-12 % over here in the US. I’m curious where you get your $50 from. That seems unreasonably high. Shoes have one of the slimmest margins in the apparel industry for a reason. Best of luck on your shoe production.

Have a great week,

Dara

Anonymous – Thanks for reading the blog and commenting!! I will take into consideration, the balmoral boots!! As far as Italy goes, the factory that I had in mind to work with, was about the same price as the English one, when it comes to Goodyear welted shoes so I just wrote about the one example, to make it less lengthy.

I am not a huge fan of blake shoes, I mean for loafers they are nice, but for a nice oxford or anything that you are going to be walking a lot in, I prefer a goodyear welted shoe. It just feels more supportive and better made, in my opinion, and that’s what I want to give my customers. I will have blake shoes, but considering that I want the majority of my shoes to be GY welted, I had that be my guiding criteria.

Spoozy – Thanks Spooz, glad that I can always count on you. Don’t forget to let me know the exact dates that you are coming up, around a month now??

Julio B. – The sad truth about that Julio, is that any shoe that you have ever seen in a store, was definitely NOT ‘handmade.’ It’s sad, but this term is thrown around like it means nothing. Sure, some shoes are hand finished, but the construction was done by machine. Therefore, I only hope to educate my future customers, to know that a well made, machine made shoe can be justified in it’s price, if you have good workers in the factory who pay attention to the details. As far as originality goes, I hate the idea of copying anyone for anything, so you will never have to worry about that.

Vittorio – For the British vs. Italian, see the first comment. As far as Bespoke shoes for 350 Euro, I cannot believe it. Nobody in Florence charged that price when I worked there. They were all over 1000 and some even over 2000 Euro. It just does not make sense, with the man hours put in and the cost of materials. There has to be machine use in that price. But thanks for commenting Vittorio.

Dollarkvn – For RTW shoes, they need to have a store presence. People need to see them, feel them and try them on. I would then need to have on hand inventory and be able to sell all of that. I could not order, from a factory, a pair here and a pair there. They would never go for it or if they did the turnaround time would be 4-5 months per order. This model works for bespoke, but I do not know any RTW maker that does this. Thanks for the comment nonetheless. I wish that I could do this though, it would make life easier.

Reto – Thanks for commenting.

Dara – I got my mark up from a shoemaker here in England. Maybe there is some misunderstanding here because, according to your input, if I were to buy the shoes from the factory at 120 GBP/pair and only take a generous 10% mark up (according to your scale of 2-12%) than I would be making only 12 GBP on each pair of shoes?? I would go out of business immediately and never be able to pay back my investors, nor myself?

Thanks for commenting anyway and for reading the blog. Enjoy the rest of your week as well!

-Justin, “The Shoe Snob”

Hey Justin,

Thanks for writing back. I got that number from several designers here in the US (hence the curiosity about the UK.). I’m not sure how they do it, but they normally make their margins on the volume, not the individual sale. Because a store generally wants at least 2x for margins for them in store. Here’s some things I do know that they do to lower their costs:

1. Min of 300 order per store/chain

1,000 is preferred.

2. Practice drop shipping from the factory directly to the store.

3. Require pre-payment in checks (lowers bank fees).

There’s a number of others, but those are the big ones I’m aware of. If you want, I could give you some e-mails for people to talk to here.

I also forgot to mention something that a lot of brands are moving to here in the US is direct shipping from an online site. Most of my designer friends find they make a lot more profit when they cut out department stores as they get to keep the 50% profit for themselves. However, you have to do more advertising.

These are all designers that use factory manufactured products that may be hand finished as the numbers may not hold true for you in Europe. I wrote simply because I was curious about how you do things across the big pond. Have a great day. As always, I enjoy reading your blog.

Thanks,

Dara

Dara – No worries, I try and respond to all of my comments, even the negative one’s. Well, looking at your 3 rules, it would seem that we are on different wavelengths, as these are the factors that seem to lie with huge companies and distributions. I will make a mid-range shoes priced from $400-$600 which will probably sell at specialized shoe stores and be bought in size runs of 12-14 at 5-6 styles with color options. So my max purchase would be less than 200 pairs. Therefore I cannot make 10 pounds/pair or I would quickly fail.

If I was selling 1000 at a time, then I can see taking a smaller mark up but I won’t be, not for a long time at least, if ever.

As far as contacts, I would be more than happy to take any that you would like to offer. I am a great believe in the power of networking.

I will definitely be looking to set up my own site for Direct to Customer shipping, but that might be a little while after initial release, as it will require holding inventory.

Well, thanks again for commenting, I appreciate the input. I am glad that you enjoy the blog too, that means a lot. Have a great week!

All the best,

-Justin, “The Shoe Snob”

Hi Justin, firstly great blog.

I shop around for great shoes and own a pair of Grenson’s made in India. They do the job and I got them in a sale for 100 quid a pair.

I bought two pairs so that they will last longer. I hear your dilemma of the price. If it I would say too high for the average customer. You would be aiming at a high end market but like me the average buyer would have to wait till a huge sale and pray we can find a size and style we like.

This is a tricky one in my opinion. While if you retail the shoes yourself for 200 pounds would feel like a fair entering the market price.

All the best and keep up the good work. Jules

Julian – Thank you!! Glad that you enjoy it. I appreciate you insight and comments. While I don’t want to necessarily reach ‘everyone,’ I don’t want either for my shoes to be for the top 5% of the population either. So I will create a nice middle ground….

-Justin, “The Shoe Snob”

Hi, i have been reading your blog and all the comments and people willing to help you progress and i ind that amazing.. I am fron north london islington and i am looking to start up a shoe line myself. I havent really got much experience in the knowledge of shoe manufacturing etc and i would like to know if you or anybody else can provide me with advice.. If you can, please email me on [email protected]

Jay – see email that I sent you.

-Justin

How many lines of the same shoe should i sale n 1 area

Anon – Sorry but I don’t understand what you are asking…

-Justin

Hi Justin, I have just read about your dilemma, I see this was written a couple years back. But I’d just like to enlighten you on my thoughts. I am from England and was importing goodyear welted shoes from India in the 90’s. 8 years ago, I felt like the quality wasn’t up to my standard so I thought I should set up a factory in India as I have great knowledge in the manufacturing of goodyear welted construction. I supply major brands throughout Europe and my goal now is to penetrate the American market. I imported all my machinery from manufacturers in the UK, so basically it’s an English factory set up in India. You talk of the monetary side of manufacturing… I use imported leathers from Italy/Portugal etc. but the expense of manufacturing is in the initial tooling up. For example Producing the lasts, the correct knieves and cutting accessories for the machines, the stamping etc. If you’d like further information of costing and difficulty and ease of manufacturing. Feel free to e-mail me [email protected].

Regards,

Anaik Jagpal

Anaik – Thanks for your comment and for your offer to help. I do appreciate that.

best

Justin

Hi Justin,

I see this post is quite old by now, but I just stumbled upon it and found it quite useful, and I wonder what you decided on. I am setting-up a new line of shoes at the moment and would love to exchange ideas and get your feedback.

You can reach me at [email protected] when you have time.

Best of luck, and happy new year !

I second Phil below. And my current contact information is: [email protected]. If you are interested at all still in this discussion!

I know this is years ago but if you trad this please contact me. I am interested in starting my line and need info and you seem to to know a lot. [email protected]

Hi, I know this post has been up for awhile. I am shoe manufacturer/consultant based in Los Angeles,CA,USA. We specialize in men’s shoes but we also do women and kids as well. We make great oxfords, monk straps, derby’s, loafers, boots, you name it! We use the finest tanneries for leather and textiles. We also work with exotics as well. I will be more than happy to assist you and give you a free consultation. We thrive off our concept: “Looks Italian, made in the USA.” My email is [email protected]. I hope to hear from you!

Why dont you start retailing your own website if the 200% of shoe price is actually nothing but some greedy retailer fleecing customers?

i think that many miss the point. Manufacturers can make anywhere. I was talking about a designer, buying from a manufacturer that sells a like product and then automatically having a more expensive product than your supplier

Hi ,

I found your blog pretty useful , as I am currently writing a business plan for a shoe line of my own, and I do want to create good quality shoes, but I keep thinking Italy would be the place to manufacturer from. I live in Canada Toronto by the way. I have no experience in the shoe market whatsoever and I’m not sure what my margins or prices would be. I’d like to retail my shoes between 300$CND – 1000$CND depending on the styles nd work put into them + the quality of materials I’d be using.I’m not sure if I should manufactur emy own shoes in Canada? or I should order to a manufacturer?can I possibly have the Italy quality in Canada if I choose to produce my product myself? what do I even need to start for that?and how much I should invest in. I know you wrote this blog a couple years ago. I’d like to know where you are now, and what you have decided and get some insight on where this plan of yours has led you.

Thanks,

Yasi

Hi,

Glad to see your interest in footwear. I am planning to launch my own label. Let me know if we could do something together. Mail ; [email protected]