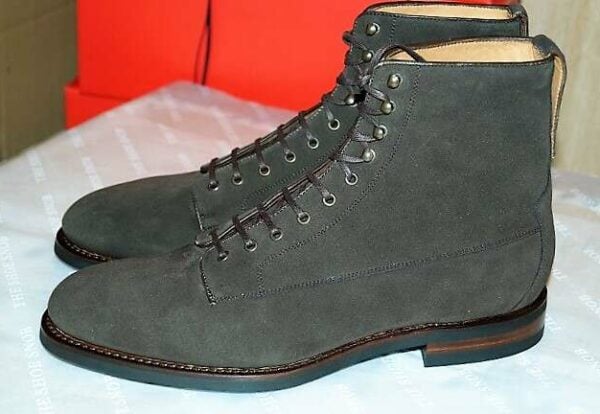

After going to the Saint Crispins factory last year (and writing about it HERE), I worked with Phillip Car (the owner) to have a Saint Crispins boot made up for me in a design that I had created but had yet to realize in my own brand. I was quite excited about it as I had never done a shoe/boot in 3 colors and had seen SC execute that idea to great success. So, I gave him my design and let them make their interpretation of it. Needless to say they did a great job and what came out is the beauty that you see in all of the pictures that surround this text.

Most of you will be familiar with the brand, but for those that are not allow me to shed some light. Saint Crispins is an Austrian Brand (I guess, since the founder(s) are from there) whose shoes are made out of Brasov, Romania in a small factory and made 95% by hand. The history is a bit more complicated. It was founded by the cousin of the current owner but who at one point had ideas of his own and wanted to start something different and thus did so. Phillip Car (the current owner) stayed with Saint Crispins and in my opinion made it what it is today i.e. one of the most recognized brands in quality footwear.

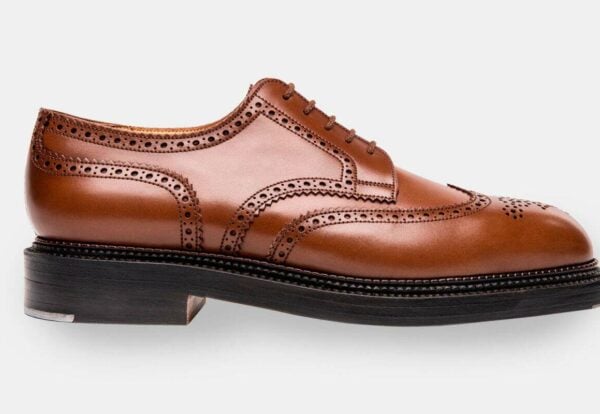

As per the shoes, well I can honestly say that there is not one thing bad about them. On the contrary, they are simply amazing as far as quality go. The comfort is probably the best that I have experienced for a RTW shoe and the making is flawless. There are certain aesthetic things that are not my absolute favorite i.e. lasts are either slightly long for my personal taste or a bit too robust (no true happy medium for me) but other than that, there is nothing that can be said to cut the shoe down for it’s make.

That being let me talk about a few of the arguments out there that are talked about by other people and put my two cents in. First and foremost, there is the issue that the shoes are 90%-95% handmade as opposed to the 100%. This 5%-10% is due to the fact that during production of the shoes, the soles are attached by a hand-wheeled machine (not some fancy new one, but one that they used way back in the day). I asked Phillip about this and he said that in reality there is no real difference to hand stitched or machine stitched soles and that doing it with the machine cuts significantly down on production time (which is a strong part of his business model and why many people love SC). And having made shoes by hand myself, I have to say that without pure snobbery involved I can agree with Phillip as a sole stitched by hand or machine really does not make much of a difference. Being welted by hand is another story, but they do that so nothing to argue there. But funny enough, when they do resoles on their shoes, they do them entirely by hand. Don’t ask me why.

Another so called fault I hear about in the online fora is the amount of leather creasing on SC shoes. It is the same issue that I have addressed time and time again but realized that there is a deeper understanding to it that I have yet to discuss and need to actually dedicate a post to it. But the fact of the matter is that all of the calfskin that SC uses is from Crust leather. Now for those that don’t know, Crust leather is an untreated (aka white/natural) leather that is meant for hand coloring after the production process. Due to the fact that the leather is not put through the entire drum dyed process, it is naturally a much softer and pliable leather with respects to regular box calf. That being, it creases easier. It’s the same reason that many French shoemakers leather creases a lot too. They also use a lot of Crust leather as they all love to patina their shoes to custom colors. But as I have said before, and will do so many more times in my life: CREASING IS NATURAL.

Other than these outside discussions, the shoes are of immense quality and comfort and although they are a price that can be hard to swallow, I can see why they cost their price. And the other upside to the brand is that they will literally make anything you want and probably have the best MTO program there is. So if you are up for spending a few extra and trying something different, Saint Crispins just might be the right avenue for you.

FYI, if you like the model it is able to be ordered. It is model 634 on the classic round last.

Very nice quality, even if I don’t like their mix-and-match pieces style 🙂

BTW, I think the resoling is done by hand to avoid damages to welt or shoe: hand cranked Goodyear machines can be quite unforgiving, if the welt is cut so close to the upper

thanks for the input Francesco!

… the reason behind hand stitching the resole is to make sure the original stitch perforations on the welt are not compromised … hand stitching makes sure that each new stitch will be placed in the original perforated hole to maintain aesthetic quality … machine stitching does not allow for accuracy when placing stitches on the welt of a resoled shoe especially when using a hand crank sole stitching machine.

The shoes are great, but that suit is spectacular!! Who’s the tailor?

Thanks Emre, I appreciate. It is a friend of mine who has worked at many of the top firms on Savile Row. Email me for further info

A beautiful make up Justin – I like the black-fading-to-grey concept. The best thing about St. C. – apart from their superb quality and exceptional customer service – is the ability to order EXACTLY the shoe or boot you want and thus precisely fill that missing piece in the wardrobe, or else explore the creative limits of your imagination. They are in the business of making shoe dreams come true.

Thanks Roger!! And yes, I agree with you. I like the last sentence.

Hello Justin,

I know you are a Bestetti admirer, so this question speaks to that somewhat – How would you compare a boot on the Novecento line to a St. Crispin boot? A bit broad, but any remarks in general between the two makers…?