All photos and process courtesy of Japanese Bespoke Shoemaker, Eiji Murata aka Main D’or.

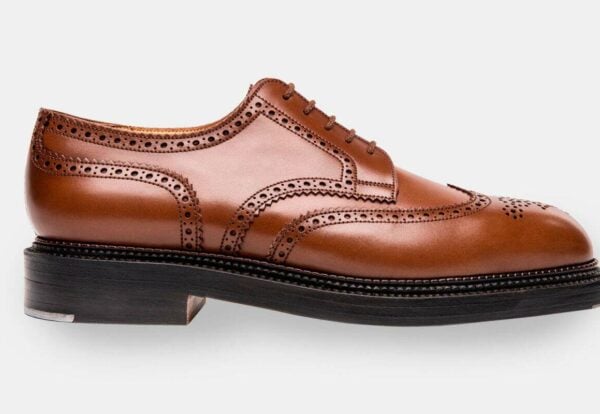

Hand-stitching an upper is no easy feat. When you look at the pictures it probably seems easy. But allow me to tell you that it is tough and mainly for the precision involved. The smallest error can result in cracking leather or crooked stitching and the shoe is pretty much ruined when that happens as there is no correcting it. But when done properly results in a beautiful finish and much more elegant and clean look than the machine stitched apron, which for me is just flat out ugly.

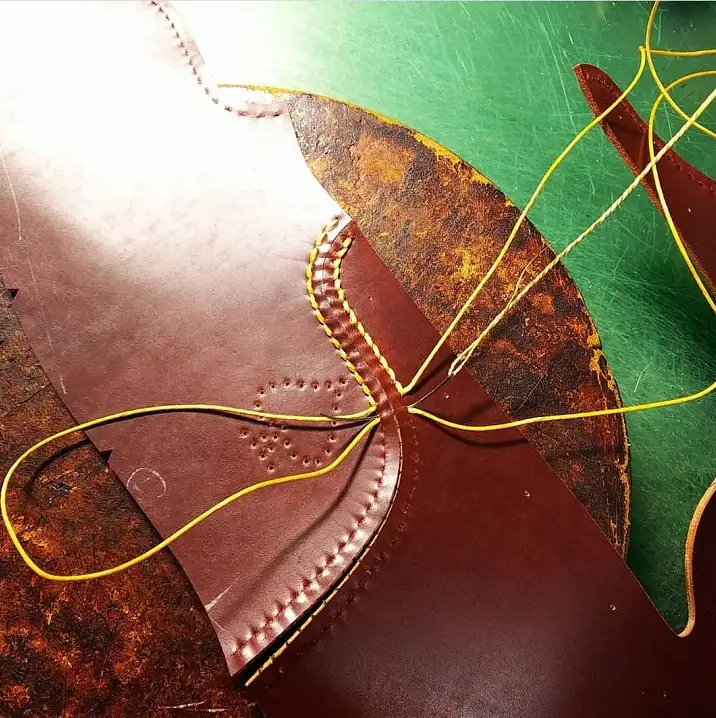

In this post, you are actually seeing two types of hand stitching, that Eiji is so kind to show us. First is the classic boat shoe type hand stitch (directly above) where you join two pieces of separately cut leather and stitch them together to form one joined piece, as Eiji did here with the heel counters. This type of handstitching I have never actually done before and while not saying that it is is easy, do think that it must be slightly easier than the other form of stitching that we will see below.

Eiji shows us here that he is doing this simply on the cut upper pieces whereas when I was taught this at Stefano Bemer, the upper was completely made and we did this process as we pre-lasted the upper to the last. I guess that he does it like this as he causes less risk for mistake. Because if you do make a mistake then you only waste one piece of vamp leather as opposed to an entire upper and lining. So in fact, his way makes more sense.

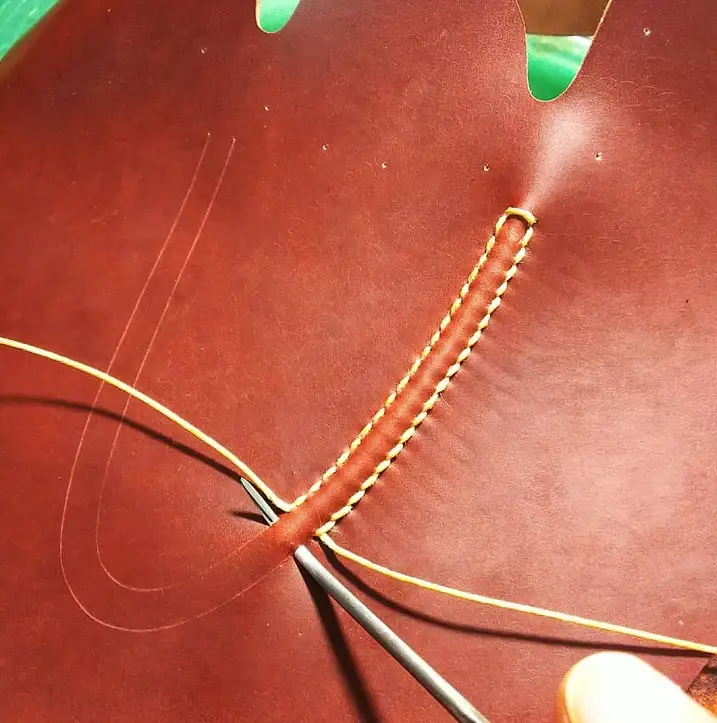

The reason that this way, for me, is more difficult is because you are making those punches with the awl at one time in two places and if you make an error in alignment, you end up with a crooked apron and it shows very easily. So you have to have precision punching here. And that is difficult. If you look carefully in the first set of pictures where he joins the two pieces, there are pre-punched holes to show you were to incision of the awl. But in the vamp there is just the magic silver pen line and no indication of where to punch through the leather. This is where the master of the eye takes place. And Eiji did a phenomenal job!

Hope that you all can appreciate this little bit of handwork that goes into many of your shoes. It is a hard process and is to be highly respected!

Justin,

Great post and explanation!

I think the first stitch is way more difficult because the awl does not pass through the entire leather i.e. enters through the grain and exit through the flesh. It enters through the grain and exits through the cut edge which is say roughly 1.2mm thick.

Eiji has to make sure that every single one of the awl exits at exactly the same distance from the grain say 0.3mm or else you get excess and unevenness once the 2 pieces are joined. Looking at how clean the finished piece just makes me think about the amount of work that has gone into perfecting this stitch, a combination of genius, dedication and pure insanity.

-Tor