I remember the first time I ever visited a shoe factory; it was Santoni’s factory in the Marche region of Italy, and being there (due to me being a shoe freak) was exactly like a little kid discovering Willy Wonka’s Chocolate Factory. The showroom was amazing, the factory floor was immaculate (especially for a factory) and shoes were everywhere. It was literally like shoe heaven. And the building I was in was just one of their three huge factories on site. It was such an experience!

But since then, I have visited several other factories, of all shapes and sizes, and one thing I came to realize in my judgment of how much I like a factory, is whether or not the factory feels intimate. As beautiful and amazing that Santoni’s factory was, I truly felt that it lacked a sense of intimacy, where people came day in and day out to just do ‘their job.’ You might be thinking ‘duh,’ that’s what work is, a job. But I mean it in the sense that one person come’s to the factory every day and sits at the same machine all day long just putting heels on, and in reality, he/she doesn’t give a shit about shoes, just getting a paycheck. This is not the case at Gaziano & Girling’s factory.

Compared to Santoni’s factory, where they employed hundreds, G&G only employs around 7 or 8 full-time workers, imagine that! And due to that small amount, you have workers there who do the amount of work usually managed by three or four people. And on top of that, several of the workers are also shoemakers, able to produce a pair of shoes entirely by hand, real artisans. So when you have a factory like this, small and with highly skilled artisans, you get that sense of intimacy, like the people who work there truly care about the shoes and how the end product comes out. And being someone who has also made shoes by hand, I can tell you that your ability of spotting flaws and discrepancies and being much more critical of a final product increases by 1000%. That being, you know if a G&G shoe is put into a box to send to a store, it is going to be damn near perfect!

In no way am I saying that G&G’s factory is great and Santoni’s is bad. They are just different. Both are amazing for what they are. I just happen to appreciate something that feels more intimate. But then again Santoni supplies to 100 times more stores than G&G, and I think that intimacy seems to directly correlate to this fact. Could be that if G&G grew to the size of Santoni, the intimacy of the factory and company would decline, who knows? Regardless, it is always a pleasure heading to historical Kettering to visit the G&G factory.

You might be wondering what the purpose of my visit was, so let me tell you. While this is not my first time up there, it has been the first time that I was able to document it for all of you, thanks to my lovely new camera. As many of you know, I am a young man on a quest to start my own shoe line, to fill a gap in the industry that I fel exists. On my journey thus far, I have met many wonderfully helpful individuals and Tony Gaziano & Dean Girling are two of those people. That being, they frequently allow me to come up to the factory to do my own projects. And with the assisitance of my good friend Daniel, I am able to work all weekend long until the wee hours of night, chipping away at heels, in which I did this trip in order to finish my 7th pair of shoes made for myself (which I will show in another post).

Well, I hope that you enjoy the pictures! Thanks to Tony and Dean for allowing me to document my trip. Until next time,

-Justin, “The Shoe Snob”

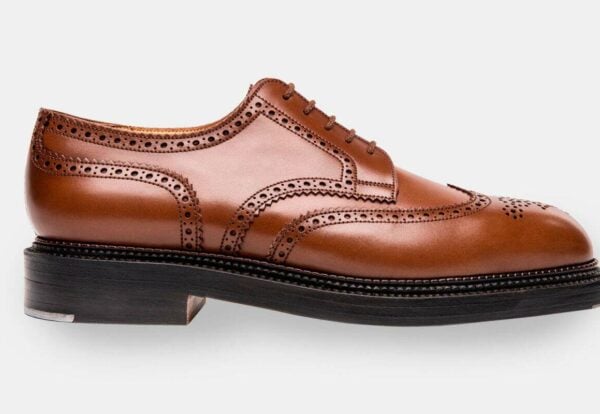

A Flawless Bespoke Shoe:

Shoes, Shoes and More Shoes:

My Friend Daniel, Chipping Away At Heels:

Hey! Awesome post, so great to see the working behind the magic. Some of those shoes make me want to cry for the emptiness of my wallet!

Do they have a factory store on site like some of the Northampton firms?

All the best!

wow…that is simply amazing. Only 7 or 8 workers?!

This is probably a noob question, but does G&G work only in the made-to-measure and bespoke realm? Or are they also in the same area as Santoni where they are making ready to wear shoes?

Amazing Post! Talk about a kid in a candy store! It definitely has the look of small work shop feel especially with only a handful of workers.

I wonder what the yearly average output is for G&G?

BTW – I can’t wait to see your 7th pair.

Thanks for sharing.

great post

i get shoes made in italy for bout 270 pounds are you cheaper than that?

Great eyecandy.

the green pairs especially.

Seriously great stuff, love the detail shots!!

Anonymous – Thanks! Glad that you enjoyed the post. Unfortunately they do not have a factory store, I think that they are just too small for that yet. But they are offering seconds right now. If you go to their website, you will see it one the news reel and can contact Dean to see what you may find for a lower price.

Joker – Yea, only 7 or 8 full-time workers and maybe 1-2 part-timers. G&G do make RTW, and are rapidly growing. In the States, they sell at Wilkes Bashford in SF, Leffot in NYC and supply the shoes for Paul Stuart in Chicago and NYC.

T.Stepat – Thanks Thomas, couldn’t say what the output is, but it is going to be quite high. They have a decent amount of stockists around the world and are only growing bigger. The 7th pair will be up soon, just have to finish attaching the button for the monk strap!

FBMS – Thanks! I actually don’t make shoes yet, just for myself. I still have a bit to learn to venture off on my own. But to be honest, I would not be that cheap.

Spoozy – Thanks man, June is coming!

-Justin, “The Shoe Snob”

Woe – Just realized that I skipped you, sorry. The green’s are nice, right! They were the best shoes I have ever seen bespoke, literally FLAWLESS!

-Justin, “The Shoe Snob”

thanks for the answer. i go to this place in milan and they’ll copy anything you give them, do you mind if i take a photo of your shoes and get them to copy that?

FBMS – Well, considering that you could do it without my permission, than no I don’t mind and I appreciate you asking. Which one would you be copying out of curiosity?

-Justin, “The Shoe Snob”

As far as output is concerned, Film Noir Buff did an interview with Tony who said they only do about 100 bespoke shoes a year. I believe they split their efforts between bespoke and RTW about 50/50 (there was a lot of stuff on styleforum). I really like that the overall output is low, but as long as they keep on hiring people who are very skilled (like actual shoemakers) and the quality doesn’t suffer, I don’t really care how much they expand. Also, the fit and finish around the heel and the fiddleback sole is just gorgeous.

I think its great that theres so many people in the UK getting into shoemaking but I think we’ve got to bring the price down. I got the famous spectators from Crockett and jones copied by this shoemaker of milan for about 270 pounds. thats a fair price. But is there a place for more shoemakers in a country where people dont even change their Nikes from one year to the next let alone clean them. Are the British the dirtiest in Europe then?

the red ones with white piping

James – Too true!! Knowing Tony and Dean, and how important it is to them that they produce the best possible product, I don’t think that anyone will ever have to worry about the quality of the craftsmanship dropping.

Maria – Don’t know where you are really going with your statements, but if you were saying that you liked my red shoes with white piping, than thank you. As far as this shoemaker creating shoes for 270 Pounds/Euros, I find it hard to believe that he did so by sewing the sole by hand. If so, then he is a dying breed because at that price, it does not even make monetary sense when you divide it by the hours worked and cost of the materials.

-Justin, “The Shoe Snob”