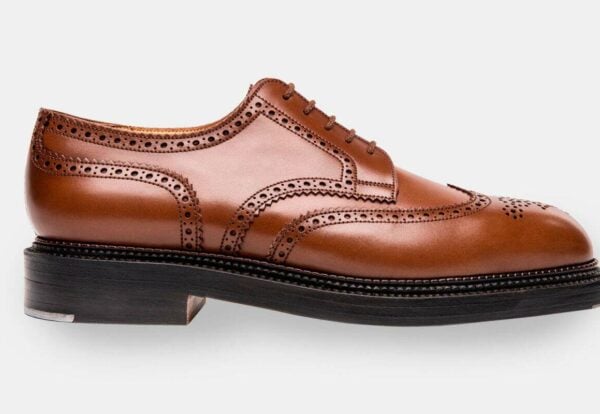

The French Sole Treatment is how I like to categorize the addition of sole guards and toe taps to your shoes, as you can see in the photo above. It is a very common sole treatment for anyone in the French-speaking world in Europe.

I always find it interesting to see how different cultures like different things when it comes to their footwear, whether it be in regards to fit, how to treat the sole, how to polish etc. Well, the combination of added rubber pieces to your soles mixed with toe plates is very common in the French-speaking part of the European world. While it is especially very common in Paris, you will also find many of those living in Geneva adding these two sole additions as well. It’s almost their staple signature.

While I am personally not crazy about adding rubber sole guards for my own shoes (because I don’t live in a climate that I feel warrants it), I find them infinitely better when the toe piece is added. I don’t know why but I just do. Maybe my fascination is purely aesthetic as I like the idea of the rubber and the metal combined.

That being, for those of you who also like to protect your soles in this fashion but live in London where not so many offer such a package deal, fret not as my good friend Tony of Tony’s Heel Bar can take care of it for you. Tony used to offer this service to all of my shoes when I lived in London many years back.

And if you live in NYC, as I do now, I recommend going to Vince’s Village Cobbler, who now takes care of my shoes.

I add very thin rubber to the soles of my shoes simply because where I work has a lot of rocks on the ground which cuts up the leather. It should also mean that the shoes last longer.

Only costs me £18 a pair, instead of the cost of sole replacement.

I usually wear down the toe parts of my leather soled shoes before the rest, but I have my cobbler just put in a leather toe “plate”, so to speak. What I don’t understand about metal toe plates is – how are they fitted given the variety of shoes out there? Soles have different sizes and shapes…leather can be cut, but metal would be much harder I would think – can anyone enlighten me?

Steel toe plates or ‘segs’ are sold in a range of different (numbered) sizes; your quality cobbler (or cordwainer if added at manufacture) will usually have a range and pick the one best suited to the size of the shoe. Beyond that, since most cobblers already have sanding wheels they can always tweak the shape to get it spot on.

anyone have an opinion on heel plates? are they uncomfortable to wear as the heel is the first bit of the shoe to strike the ground?

How long does this process typically take?

Cheers