gemming allows for this waist in a RTW product

Lately I have been hearing a lot about gemming, mainly blog readers telling me that they had read about it elsewhere, not only on the forums but also from other bloggers claiming that gemming is bad, as it apparently minimizes the lifespan of the shoe. Claims have stated that after 3 to 4 resoles, the gemming will break (either the rib or the cement will come loose) and then make the shoe un-resolable. They claim that handlasting and hand welting are far superior (which they are, but not practical for mass production) or the other alternative, which most probably don’t know about (as it is so rarely used) is the machine that cuts the rib directly from the leather insole. It is then claimed that many top shoemakers are in fact using the gemming method and because of this they are “ripping people off” with their ‘so-called’ inferior product. Getting all of the heresay apparently claimed by others out of the way, allow me to put my two cents in.

gemmed insole

Let me first start by saying that 95% of everyone whose goodyear welted shoes are made in a factory is using the gemming method, that is everyone: John Lobb, Gaziano and Girling, myself, Crockett & Jones, Edward Green, Allen Edmonds, Alden etc…. So according to the people that claim this theory of gemming being bad and thus creates an inferior product, they are all basically saying that these brands’ products aren’t worth the long standing reputation that many of them have. Thats a bold ideology. So what is the alternative? Well, it would have to be using a much thicker and thus more expensive insole to cut the wall that holds the upper and the welt, by hand. However doing this process by hand then adds at least an extra 4-5 hours of shoemaking to each pair of shoes, not to mention the extra costs to them too. This might be fine if your workers are being paid per piece or earning far less than the British or American standard of minimum wage. It might also be fine if you are only producing 100-200 pairs per month, but not when you are making 1000-2000 per month, such as your precious Allen Edmonds and Crockett & Jones are doing. The other alternative, as stated before, is using the rare machine, like J.M. Weston reportedly does, that instead of using gemming, actually cuts the rib into the insole. However, this method limits you in doing certain things, like extremely tight waists, as you admire from G&G. There is also no conclusive evidence (whatsoever!) that this method actually last longer than gemming.

handwelted and hand cut rib (holdfast)

Assuming that British shoemakers earn around �10/hr, thats an extra of at least �50 cost (factory cost, not retail) to each pair of shoes, not to mention the amount of shoes that wont be made due to loss of time. That would probably add an absolute minimum of �200 to your average Crockett & Jones benchgrade, just to get 5-6 resoles instead of 3-4 (or in some exaggerated suggestions 1-2), of which your upper probably wouldnt withstand anyway. If you rotate 3 pairs of shoes, using shoe trees and regular nourishing of the leather, by the time you got to 3 or 4 resoles on them all, at least 20 years would have passed and you would have gotten your precious money out of them. And who wants shoes that they have been wearing reguarly to last more than 20 years anyway? Dont be cheap! Buy new ones for crying out loud!

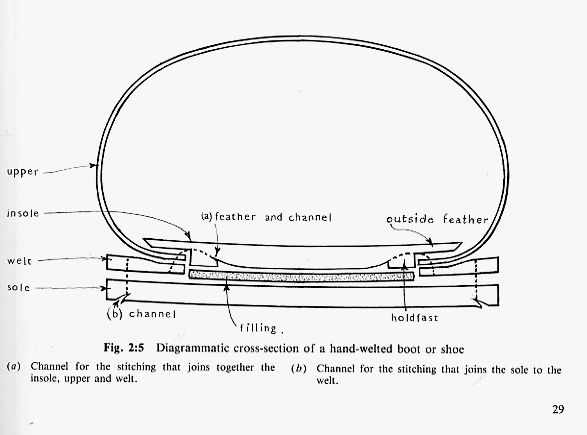

If you look at the picture above, you see where it says “holdfast,” well this is bit that connects the upper to the insole, and then the welt to the insole. When doing this by hand, you can cut a holdfast (and/or rib) into the insole that is maybe 1-2mm high and 4-8mm (depending on country preferences e.g. Italy (4mm) vs. England (8mm)), which is quite strong and controlled by hand the entire way. However in gemming this holdfast is like 3-4mm high and about 1mm wide (due to the fact that a machine is stitching all of the thread and it therefore needs to be tall and thin). Now the alternative of the machine who cuts the holdfast directly into the leather insole, still needs to create the same type of holdfast (in height and width) as the canvas one used in gemming, and there really is not any conclusive evidence that the leather holdfast is any stronger than it’s gemmed counterpart. The other argument could be that it is cut into the insole as opposed to cemented on, as in the case of gemming. And while I am not a fan of cemented soles myself, I have seen many that have lasted a very long time, and being a sole, they are subjected to constant strain and moisture from rain (which is what slowly breaks down cement holding). But being inside the shoe (and covered by cork), it is less likely to separate as quickly (as in years and years) as a cementing would on the sole. Therefore, there is really no argument that using leather instead of the canvas alternative (as for doing things strictly by machine) is any better. If it was, then G&G, JL and EG would be out of business for their shoes would be falling apart quickly. But there not, are they???? Sure, cutting the holdfast by hand and then welting by hand is much better, but it is simply not practical for selling shoes at a reasonable price when manufactured from a country that pays their workers justified wages.

doing it by hand….it takes a LONG TIME, trust me I have done it!

Now as a counter-argument to my own discussion, I will say that using all genuine leather products inside of a shoe and doing it in the hand method way is always going to be better, but it does not make it the fact that the new ways make RTW shoes crap. Granted vintage shoes, made in the early 1900’s, were in fact much better made than are the shoes of today (in terms of all around quality), as there was a lot more handmaking involved, as well as better materials but the world was a different place then. Leather was in more supply. Now a days, good leather is becoming more scarce, and inevitably more shoemakers are fighting for it. Wages are higher than they have ever been. People are also more lazier than they were before. Pride in one’s product was more important then, getting your paycheck is more important now. Work ethic/quality is not the same. It’s more about profits and turn around. But this still does not mean that shoes today are not good (or even great for that matter), just different. And it’s not the shoemakers fault. It’s the way that the world is structured. Prices are simply too high, cost of living is absurd. In order to make it in this day and age, things have to be sacrificed. And what’s even more so, is the consumer, all of you, expect the best at the lowest cost. You guys have it all backwards. You want G&G quality at Meermin prices. It doesn’t work. Something has to give in order to get low prices….And so, gemming is used to save time and cost, to get you a lower price (or maybe the company a higher profit). Whatever it may be, it does not change the fact that a G&G who uses gemming, is going to last any less than a JM Weston who uses the machine that cuts the rib directly into the leather….. there is simply no evidence for that, and that is what this all boils down to….

So is doing things by hand better than gemming?…..Yes. Well then is gemming bad?…. No! ….Why not? Because in reality unless you are the type of guy to wear one pair of shoes day in and day out it is not REALLY going to affect the lifespan of your shoes, not a lifespan that you are going to notice anyway. If it was so bad, you think all of the greats would be doing it? NO! So why is this even a discussion. Well because there are many people on the web who just simply love to start talking bad about something (or simply love to compare apples and oranges, i.e. handwelted vs gemming) just for the sake of it, to do their best to prove a point and be heard. But more often than not these people have no real experience in manufacturing nor are even using common sense when saying these things as if they were they would have realized that if no one used gemming and instead did things by hand, then no one could afford shoes coming out of England or the States. That is common sense by using simple mathematics…. So to all of the iGents who are bashing this method, please realize that all of your favorite shoes that you have loved for years, been comfortable, supportive and “well made” are using this method…..

Oh and by the way, I have just started my own Tumblr page for J.FitzPatrick Footwear, so check it out should you want to stay up to date:

Nice post, Justin.

I agree with you on both points – I like the idea of hand-welting, and believe it to have more integrity (both artisanal and structural!). But also I think your point is dead right: for all my or anyone else’s pontificating on StyleForum about G&G etc being gemmed, we all wear gemmed shoes anyway. And it’s been a long time since I wore out a pair of shoes.

Goodyear welting, which as you said is 99% gemmed, even from the top makers, is held up as a standard of quality all over the world for a reason: for most people, it works very well and can last a lifetime. Certainly I’ve had (and have) pairs for a decade or more that show no sign of gemming failure, despite gross ill-treatment in some cases. And those are much cheaper, lower quality shoes than John Lobb or Edward Green produce.

I think it’s a fair question to ask, if you’re selling shoes for �800, maybe whether it’s worth going the extra mile for hand welting. But if we want our J Fitzpatricks for �300, there’s no excuse for moaning. There is always a better shoe, a more “hand-made” shoe, a more “artisanal” shoe, or just a shoe you or I like more than the next one. But I share your conclusion: writing off goodyear welting and gemming is simply hysterical. It accounts for 99% of the world’s good shoes.

Excellent Justin! Very well said.

Only a minority people can afford a pure bespoke shoe collection. The discussion exists because lots of people knows the price of everything, but the value of none.

The Reading Guy

I was under the impression that Vass sells his cheapest handsewn RTW shoes for 390� (http://www.vass-cipo.hu/Arlista/VassCipoArlistaEng.pdf). S

o, with all due respect, maybe there is a way to produce decent shoes and sell them with decent prices.

As manufacturer of footwear, I want to give my opinion about the topic.

He is not bad Gemming, in fact it is very good.

But he is a stupid to want to compare it with the handmade, an Audi is not bad but certainly it is not a Roll Royce, and what is mas important it does not try to be. A market exists for every thing, which is important is that the manufacturer is honored and says that it is what selling this one, Inside the Gemming there exist many ways of producing it and qualities and % of workforce, not they all are equal. This also happens in the shoes handmade.

Enrile

UK minimum wage is Euros 7.30, compared to Hungarian minimum wage of Euros 1.70.

So yeah, it is possible to make hand-welted shoes cheaply. But only if everyone making them is sufficiently underpaid.

Really like this article (as I do EVERY one of Shoe Snob’s articles). Agree that a gemmed shoe is really fine, and that it will be VERY rare to see that gemming fail. I only have an issue when high-end makers sell shoes at $1000+ prices and make the “handmade” claim. Goodyear is not “handmade”. It utilizes a machine and ultimately is held together by glued on textile. I believe that there is an “ego aspect” to the $1000+ shoe purchase, and that at this price point, many buyers really DO want a “handmade” shoe. For honesty’s sake, the “handmade” part should be dropped from the marketing, IMO.

I’ve seen comments from shoe factory repair staff which say that gemming failure is extremely common. These pretty much corroborate what the artisan makers say – that gemming failure is a matter of when, not if. The wearer probably does not notice it as such because the welt stitching and pasting keep the shoe together. But this failure will shorten the life of the shoes and lead to distorted shape. If I pay �400+ for a pair of shoes, then yes, I will want them to last longer and look good for longer than a pair costing �150 or less. (And I hate the waste of having to buy new shoes when the same materials could have been used better to make more durable product.) But they probably won’t if they are made by the same construction process. If you pay �400+ for a pair of gemmed shoes I think you are paying for the name, that is, being played. Just my 2p worth. Sites like this one also have a vested interest in the matter as they are marketing gemmed footwear.

Economic conditions being what they are you can;t make handmade shoes e.g. in the UK for �400 prices. But this doesn’t justify spending “high end” prices on shoes which are mass produced. If more people were well informed and refused to pay above the odds for standard construction then manufacturers would have to respond somehow and up their game. Maybe wages of artisans would then also improve. It also saddens me that it is in fact *not possible* to learn artisan shoemaking in college in the UK any more. Where is the next generation of artisans going to come from?

First off, whether or not I have my own shoe line that has goodyear welted shoes makes no difference, as if you have read this blog for longer than a week/month/year you will know and see that I have always promoted goodyear welting from all brands, even though I have learned bespoke (hand welted) shoemaking too. And my shoes anyway are not +�400. Secondly, tell me what shoemakers (outside of rubbish designer brands) charge +�400 and mass produce shoes, most likely in the way that you are meaning? Edward Green, G&G, John Lobb etc all make shoes on a very small scale compared to those like Church’s, C&J and the likes, and even they are still small when you start thinking about other brands like Grenson, Paul Smith or any other high street brand. Thirdly, saying that gemming failure is a matter of ‘when’ is probably the most naive thing I have heard as it is the same as saying that the upper cracking is a matter of ‘when,’ or that the blake stitch is going to come undone is a matter of ‘when’ or that the glue from a glued shoe is going to separate, again being a matter of ‘when’….the shoe lifespan is simply a matter of ‘when.’ This argument is so stupid and frankly hypocritical by all those involved as I guarantee that everyone that has commented wears and loves their goodyear welted shoes….There is a reason that people swear by EG, G&G and the likes and that other lower end makers are not as good. If you really knew anything about shoemaking you would understand that at this level you are not paying for a name, but rather leather quality/attention to detail i.e. skilled artisanal work (time), and simply higher wages due to the country the shoe is made in…..Sure, when you buy Berluti’s, you are definitely paying for a name, and partially when getting Lobb’s but not for EG and G&G, whom still maintain honest prices when taking into account the cost of the product and the ability to make a business run smoothly through a healthy profit margin, the same that all shoemakers need to in order to grow their business….

At the end of the day, this is a silly argument made by those that really know nothing about shoemaking and just want a reason to try and cut someone or something down as they really have nothing better to do. If this argument was valid then all the successful shoemakers that produce these shoes would not be where they are today, or it would simply be the greatest scheme in history: making shit shoes and charging �400 for them, yet people swearing by their quality (even though the shoemakers are just ripping them off)…..give me a break man….

>whether or not I have my own shoe line that has goodyear welted shoes makes no difference, as if you have read this blog for longer than a week/month/year you will know and see that I have always promoted goodyear welting from all brands, even though I have learned bespoke (hand welted) shoemaking too.

I fail to see how that contradicts your having a vested interest, sorry.

All the brands you listed use gemming and some of them charge the earth. Does it really make a difference to this argument if they do so on a smaller scale than other, cheaper brands?

your argument was to try and strengthen your statement through saying that I had a vested interest, yet I was pointing out that even if I did not, I would still be arguing the same thing, as I have always promoted goodyear welting, and thus gemming…even before I had a “vested interest.” As per your last statement, whether they charge the earth or not, does not have anything to do with the argument that simply because they use gemming that means that they are ripping people off as according to some “the gemming will inevitably fall apart”….look now I am getting bored, basically this is about people who know nothing about shoe manufacturing making statements online that they really don’t know anything about, but are just saying it to cut people down….

“when not if” is obviously shorthand for a more precise statement. If you deployed charity in interpretation you would see that. But your intention here is simply to defend gemming.

my intention was to put to rest statements made by people who have never set foot in a factory, never made a pair of shoes and therefore don’t really know what they are talking about when they make naive statements about gemming falling apart before the shoes lifespan would otherwise be up nor the idea of why a shoe costs what it does…..not to defend gemming, rather to hush people who simply love to talk about what they really don’t know….. no need to respond, as I am so over this argument, believe what you like it makes no real difference to me….

Give it up Justin, you really are just a cretin.

and what does that make you? Especially as someone who loves to leave pointless negative comments that would never bother me but thus continue to read my blog even though you dont seem to like it nor me?? You clearly put too much thought and time into your own life on a cretin…maybe you should get a life

Self appointed ‘Shoe Snob’ (demonstrably distinct from ‘aficionado’) defends gemming!

“there really is not any conclusive evidence that the leather holdfast is any stronger than it’s gemmed counterpart.”

An assertion, your assertion, but not a fact.

You are quite amusing. Enjoy reading the blog and have a great time thinking of the next pointless comment to write. Oh, and thanks for boosting my stats!

your argument was to try and strengthen your statement through saying that I had a vested interest, yet I was pointing out that even if I did not, I would still be arguing the same thing, as I have always promoted goodyear welting, and thus gemming…even before I had a “vested interest.” As per your last statement, whether they charge the earth or not, does not have anything to do with the argument that simply because they use gemming that means that they are ripping people off as according to some “the gemming will inevitably fall apart”….look now I am getting bored, basically this is about people who know nothing about shoe manufacturing making statements online that they really don’t know anything about, but are just saying it to cut people down….

I have a question as a shoe and custom last maker… When I was only a repairman getting trained for the first time I had the opportunity to resole my dad’s old Church’s of 35 yrs. as the last person to sew a new sole hadn’t removed the old stitches from the welt or used a machine with the same stitch count. The welt was so perforated I felt it could only be sewn well by hand. When I re-cork it, it looked to me as if the holdfast was leather and not gemmed but admittedly I didn’t have as good an appreciation of what I was looking at back then. So assuming it was leather, was it possible with older machine models to hand cut a holdfast and use a goodyear welter to sew the welt or does one have to use a machine like the one you described to cut a specialized holdfast? From what I could understand in John Bedford Leno’s The Art of Boot and Shoemaking ca.1885, (pg. 188 fig.87) that seemed to be the case as no holdfast cutting machine was described elsewhere in the book? As a shoemaker whose only ever made shoes by hand, (mainly to test my last making skills), I would like to one day offer quality shoes built around a better last design and I’ve been trying to think of ways to combine hand lasting with goodyear welting so as to offer shoes at an economical price tag. Information about what modern machines are needed is hard to come by let alone the older machinery and I would like to know the name of that holdfast making machine to see if there are any old ones that can be found? Also if you have any information on the type of older goodyear welters capable of sewing through a normal holdfast that would be equally helpful. I wonder, is it possible to make a kind of hybrid holdfast by making an angled incision in the insole and using a bone folder to fold up the flap the way some eastern european shoemakers hide the outsoling seam?

1- Where does the holding of the shape come from?

The pressure from the foot pushes the leather outwards. There is a rapid stitch between the sole, midsole, and the welt. This docked welt is what acts as a stop point to that pressure and what holds the outer shape of the last used for the shoe. When closing the shoe the gemming will define the position/shape that the welt follows when the welt-upper-gem are stitched together. Then the welt, midsole and sole are rapid stitched, at this point the role of the gem is no longer holding anything together, from then on the shape of the shoe will be held in place by the welt-sole rapid stitch, the “docked welt” I mentioned earlier. Trying to make people believe the gem holds the shape and the shoe together is f***ing ludicrous and it denotes that people saying so don’t comprehend basic engineering concepts, they can’t be taken seriously. If the gemming fails the only thing that maybe happens is that the insole gets to be a little loose (it’s not going to fail 270 or 360 degrees), that is if the cork filling doesn’t hold it in place.

2- The economics. Justin made very clear.

My grandfather adviced me not to argue with idiots, they will bring you down to their level and beat you with experience.

This anti gemming view comes from a bespoke boot maker who posts on Style Forum. A few years ago I spoke to Dean Girling about this issue given the furore on Style Forum. Dean was a true gent and spoke with me at length. He said that he’d never seen gemming break away and that Goodyear welted gemmed shoes will take just as many resolves as bespoke handwelted shoes. As far as I am concerned Dean is the Master and I fully trust him and what he says.

I’m still not exactly clear what “gemming” is. Is it a process or a component of the shoe?

it is a process of stitching the welt to a canvas rib (like a wall that sticks out and is cemented/onto the bottom of the insole)